Corrosion Protection Layer for Magnetic Recording Media

Opportunity

With a clear cost advantage, hard disk drives remain the most popular data storage media despite competition from solid state drives. In the third quarter of 2019 alone, an estimated 83 million hard disk drives were shipped globally. Buoyed by demand, the global market for next-generation data storage technology is forecast to grow at a CAGR of 12.5% from 2019 to reach US$115 billion by 2025. However, the industry needs to keep pace with users’ demand for ever-greater storage density.

Storage density of hard disk drives can be partly enhanced by reducing the magnetic spacing, which is the distance between the magnetic read head and the magnetic layers. Since an essential contributing factor of the magnetic spacing is the corrosion protection layer, reducing the thickness of this layer would enable the magnetic media to have higher storage density. Graphene is possibly the thinnest known material and practically impenetrable, making it a desirable choice for corrosion protection layers. But conventional graphene deposition methods, which occur at temperatures of 800°C to 1,000°C, make it impossible to incorporate graphene into hard disk drives directly as the high heat would negatively affect the magnetic properties of the underlying magnetic layers.

Technology

This invention relates to a method of fabricating corrosion protection layer for magnetic data storage medium. The corrosion protection layer comprises 2D materials such as graphene, boron nitride (BN), or a combination thereof. The method allows the corrosion protection layer to be grown directly on the magnetic medium at temperature below 300°C which is much lower than the conventional temperature of 800°C to 1000°C. Such low temperature will ensure that the magnetic properties of the underlying magnetic layers will not be affected.

The corrosion protection layer is formed using laser-based chemical vapour deposition process by injecting a carbon-carrying gas (such as methane) into a chamber containing a magnetic recording medium, decomposing the gas and depositing one of the decomposed components to form the corrosion protection layer on the magnetic layer. The gas is decomposed using the energy of light from a pulsed laser beam having a wavelength of 190-400 nm. This photodissociation of the bonds of the gas at low temperature of 300°C or below is different from the conventional pyrolysis of the carbon containing gas which occurs at a much higher temperature. The corrosion protection layer created is ultra-thin (1.2nm) which enables the magnetic hard disk to have higher areal density.

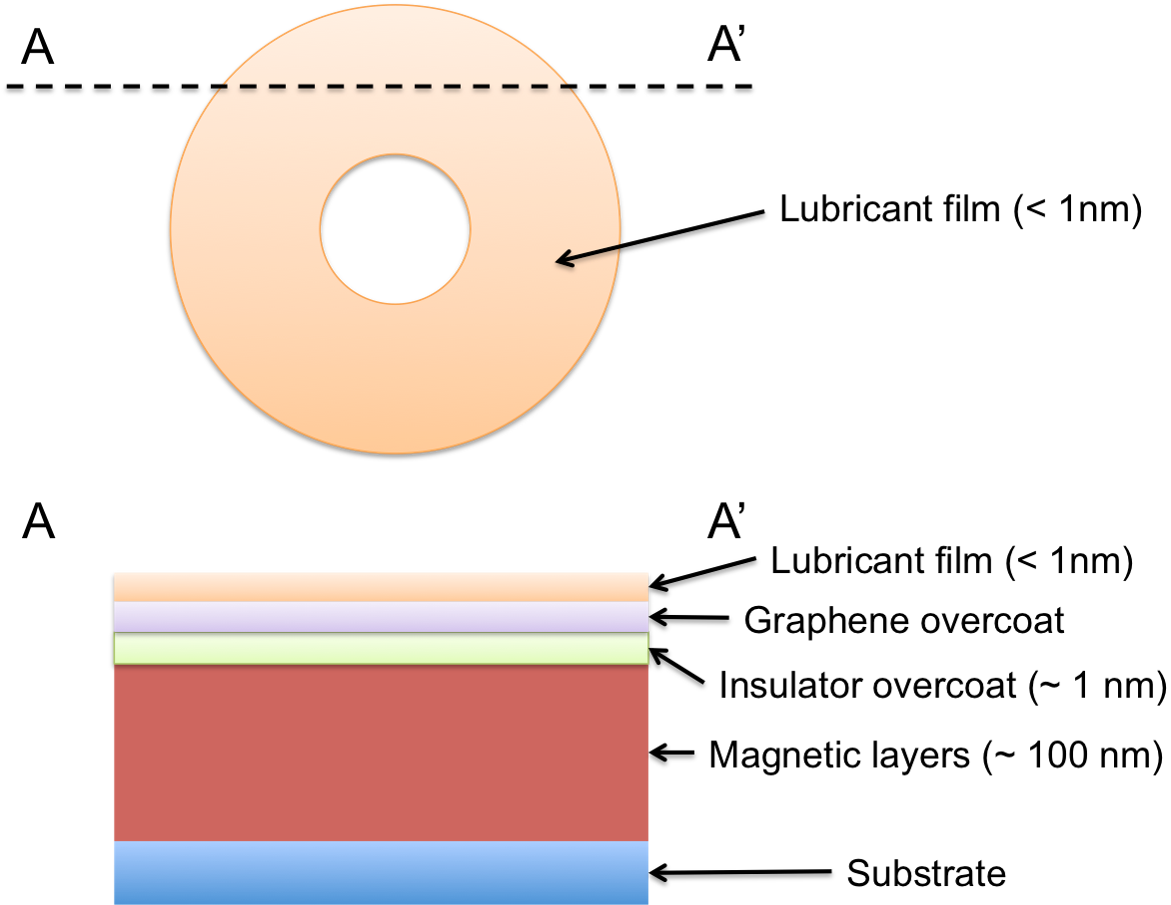

Schematic of a magnetic data storage disc containing an insulator layer and a graphene overcoat layer on top of the magnetic layers