Moving Towards Molecular Electronics with Novel Electrode Design

Opportunity

Compared to the massive machines of the 1940s, today’s electronic devices are compact, yet more powerful than ever. This is made possible by creating progressively smaller electronic components and fitting these within a given area of silicon wafers. While Moore’s Law stipulates that the number of transistors that can be built into a silicon chip doubles every two years, it is increasingly becoming harder to build even smaller components.

Conventional silicon-based electronics also has other limitations, including the production of excessive heat and electron leakage from one device to another. These have highlighted the potential of alternative electronics on a molecular scale. As suggested by its name, molecular electronics aim to use molecular building blocks to fabricate electronic components-opening the doors for high-speed, high-density devices with low power consumption as well as a deeper understanding of the mechanisms surrounding molecule-electrode interfaces.

Despite their promise, molecular electronics are made of “soft” materials like gels and living tissue that cannot withstand the rough fabrication methods typically used to establish electrical contact. Such techniques typically damage the molecules and limit the electronic performance of resulting devices. This has fueled interest in finding more effective, reliable and reproducible means to form electrical contact with soft materials.

Technology

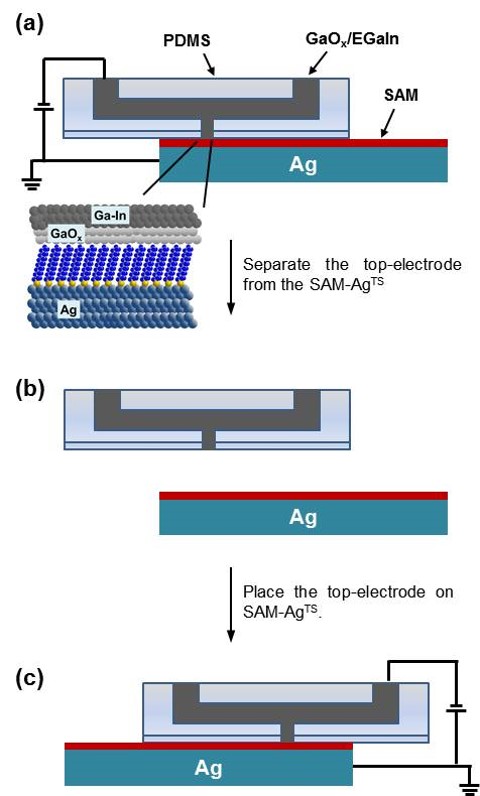

The invention describes the reliable and non-destructive electrical contact between an electrode and soft materials for molecular electronics. The fabrication of the electrode begins with the molding of microchannels in the silicone polymer polydimethylsiloxane (PDMS), which acts as an insulator. A liquid metal alloy of gallium and indium is then injected into the resulting PDMS microfluidic chip, where they are stabilized. The alloy is a non-Newtonian fluid, which means that it behaves as a liquid within the microchannels when pressure is applied and returns to a solid state when the pressure is relieved.

Reversible electrical contact is then established by stamping the electrode on the target soft material surface such as a self-assembled monolayer of molecules (SAM) formed on a metal substrate. It should be noted that the area of electrical contact can be adjusted by modulating the size of the molds shaping PDMS. Aside from producing devices with good electrical stability, the proposed method is also gentler compared to conventional fabrication methods and much easier, as there is no need to fabricate the PDMS microfluidic chip in a clean room.

The electrode is also reusable, further reducing costs. With its ability to reproducibly and reliably form electrical contact with soft materials, the patented technique represents a crucial stepping stone for building future molecular electronics.

A schematic diagram of the electrical contact of the invention.