Industrial Liquid Separation at Room Temperature

Opportunity

Liquid separation systems are fundamental to a vast number of modern industrial applications. Conventionally, to separate and isolate compounds of interest from a liquid mixture, evaporation methods are used. Heat is applied to turn liquid into vapour to obtain gases, which are then collected. The process is costly as large amounts of electricity and the extensive use of thermal isolating materials are required. Moreover, high-temperature treatments are unsuitable in many instances because heat can have unwanted effects on the chemical or biochemical composition of the mixture. This is particularly true in the pharmaceutical, food & beverage (F&B) and biofuel industries, where mixtures often need to be processed at room or lower temperatures.

Technology

This invention relates to a system for the separation of liquid mixtures using the evaporation method while ensuring that the liquid mixture fed into the system is maintained at room or lower temperatures. It achieves this through capillary evaporation in porous materials that have an enhanced selectivity effect created by the use of a novel graphene-based nanocomposite coating. This is combined with the accelerating evaporation and mass transfer effect of a dragging gas stream.

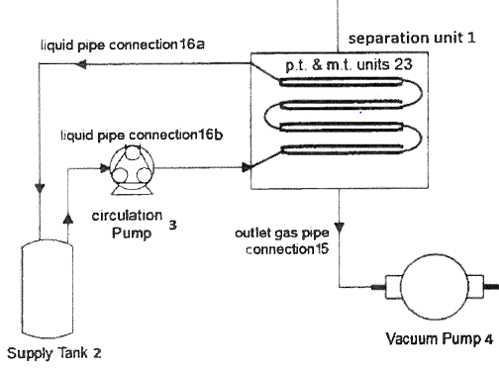

The separation process occurs inside a separation unit which contains the phase transformation and mass transfer units. The phase transformation and mass transfer units comprise a series of modules of porous materials with graphene-based nanocomposite coating applied. The liquid mixture is pumped into the modules in specific flux conditions to enable phase transformation. Outside, an evaporation dragging gas stream accelerates the phase transformation and drags the separated vapours through the porous material and into the gas stream to be collected separately.

A section of the liquid phase separation system.