Efficient Ultrasonic Pump with High Fluid Pressure Capability

Opportunity

In 2019, the global market for pumps exceeded US$76.5 billion and is forecasted to grow at a CAGR of over 2.9% from 2020 to 2026. Within the pumps market, centrifugal pumps take up the greatest share—being used in a wide range of industries, including chemicals, food processing and wastewater treatment.

Conventional centrifugal pumps are used to induce flow of fluids through a pressure difference. Due to this mechanism, the maximum pressure head achievable is dictated by the external diameter of the impeller and speed of the rotating shaft. For applications requiring a high pressure head, a large pump with a high energy consumption is needed.

Technology

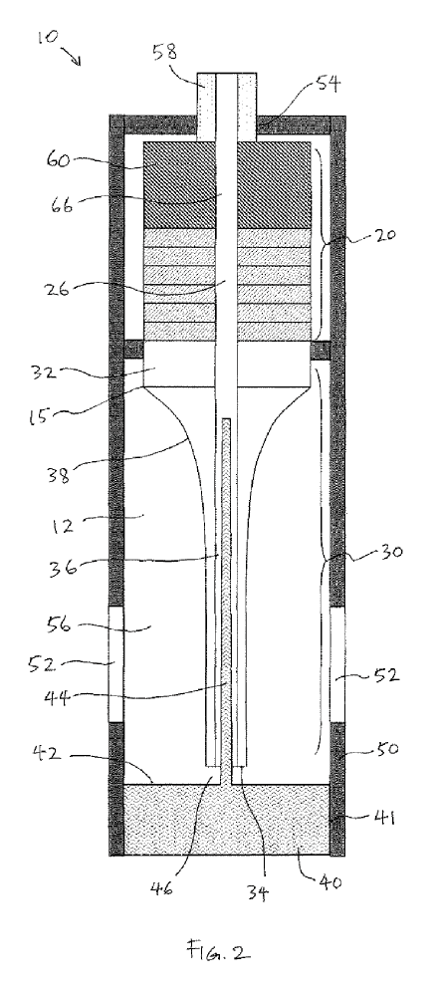

This proposed technology is an ultrasonic fluid pressure generator, with the capacity to generate a high pressure head in fluid. Used as a pump, the ultrasonic fluid pressure generator comprises a transducer, a reflecting condenser and a casing. The transducer is made up of a piezoelectric actuator and a displacement amplifier, where the displacement amplifier is connected to the actuator at one end, and has a free vibrating tip at the other.

To achieve high vibration amplitude at the vibrating tip, the amplifier tapers towards the tip—so a lower vibration velocity is required from the actuator. The actuator thus not only needs less energy to operate, but also produces less heat—increasing the pump’s reliability. The displacement amplifier is also preferably made of titanium (or equivalent), which is capable of generating high vibration velocity while resisting corrosion. In this set-up, an overall vibration amplification ratio of about 15 to 20 can be obtained, producing a high pressure in the fluid.

Besides being used in a pump, the high pressure head generated by the ultrasonic fluid pressure generator can also be used in a wide range of applications, including pressure regulators, hydraulic actuators and microfluidic devices.