3D-printed Integrated Horn Antenna for

Ku-band Satellite Dishes

Opportunity

In an increasingly interconnected world, satellites play a crucial role in transmitting and receiving information across large distances. Amongst them, Ku-band satellites are some of the most pervasively used globally for satellite communications-in applications such as broadcasting, navigation, space research and telecommunications.

As Ku-band offers robust coverage and requires smaller satellite dishes, it remains a popular choice. The global market for satellite communications equipment is expected to grow from US$22 billion in 2021 to US$53.7 billion in 2026 at a CAGR of 19.6%.

At present, the horn antennae in Ku-band satellite dishes are fabricated using traditional machining processes-which involve considerable material wastage and complicated assembly. Complex structures also run the risk of being overly bulky and unstable.

Technology

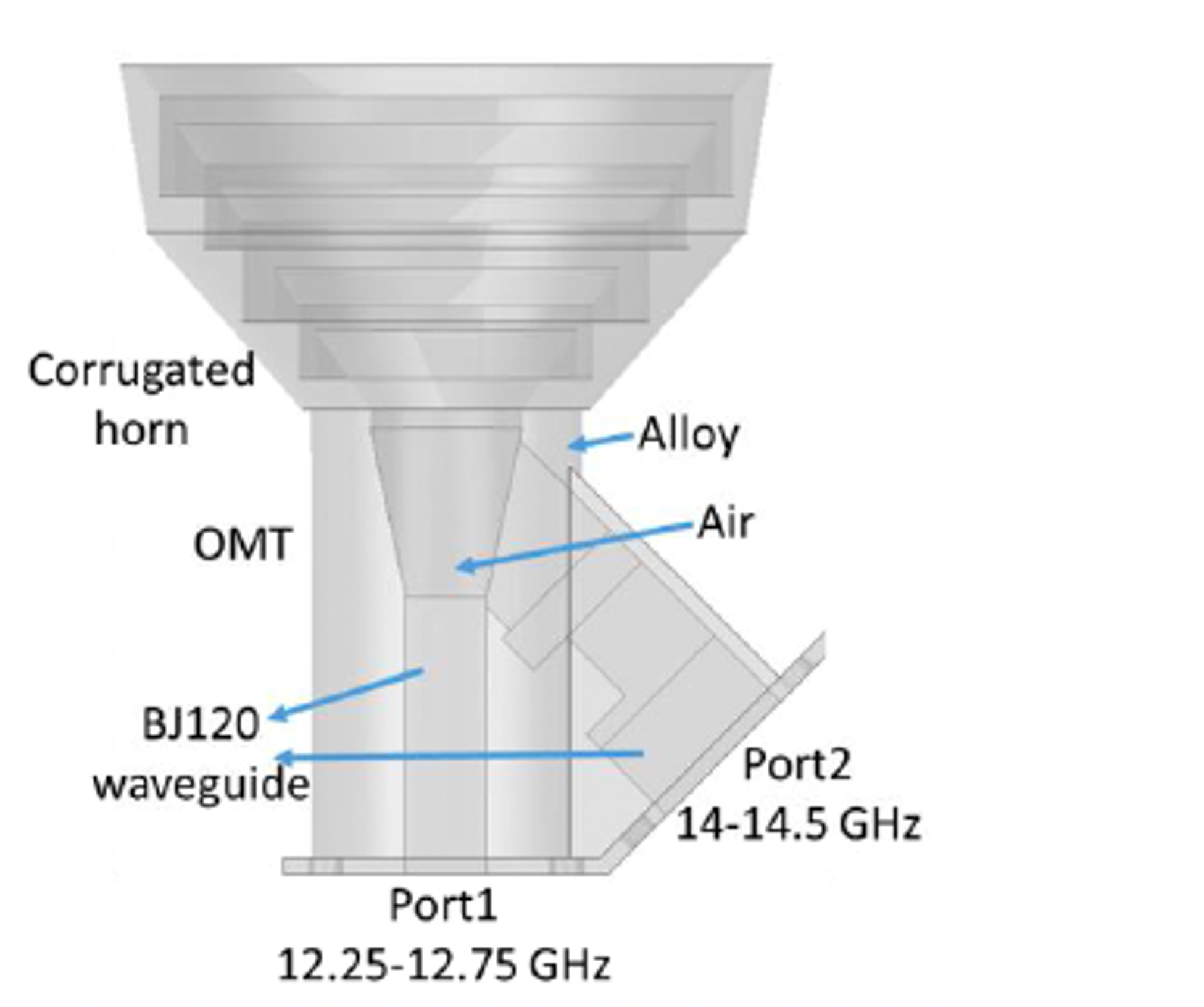

This invention describes a 3D-printed integrated horn antenna with orthomode transducer (OMT)-fabricated through an automated design process based on the Grey Wolf Optimiser (GMO). As the process is fully compatible with metal 3D printing, this cuts down on material wastage during fabrication. The removal of additional steps such as assembly and alignment also reduces costs and time needed.

Furthermore, the design stage is accelerated through automation-making large-scale and efficient production possible. The GWO algorithm optimises the horn and OMT, resulting in light, compact and stable structures. The horn antenna produced is over 30% smaller than comparable compact machining-based models operating at the same frequency. In addition, by running these optimisation processes in parallel, the overall design time is shortened to a day.

Compact 3D-Printed Horn Antenna