Self-sustainable Conversion of Plastic Waste to Carbon Nanomaterials

Opportunity

Many of commercial plastic waste treatment involve incineration, generating high footprint, high emission of harmful gases, with no value-added products.

Some of commercial plastic waste treatment processes involve cleaning, melting, and powdering to recycle for second use, but with problems of contamination from the first use.

Some commercial plastic waste treatment processes involve pyrolysis non-catalytically or catalytically to produce biodiesel, but with high energy consumption on the pyrolysis.

The global plastic waste management market was valued at around 35.4 billion U.S. dollars in 2022. This market was projected to grow to roughly 37 billion dollars in 2023, and reach nearly 44 billion dollars by 2027.

Technology

This invention relates to a method of utilizing plastic waste to produce carbon nanomaterials.

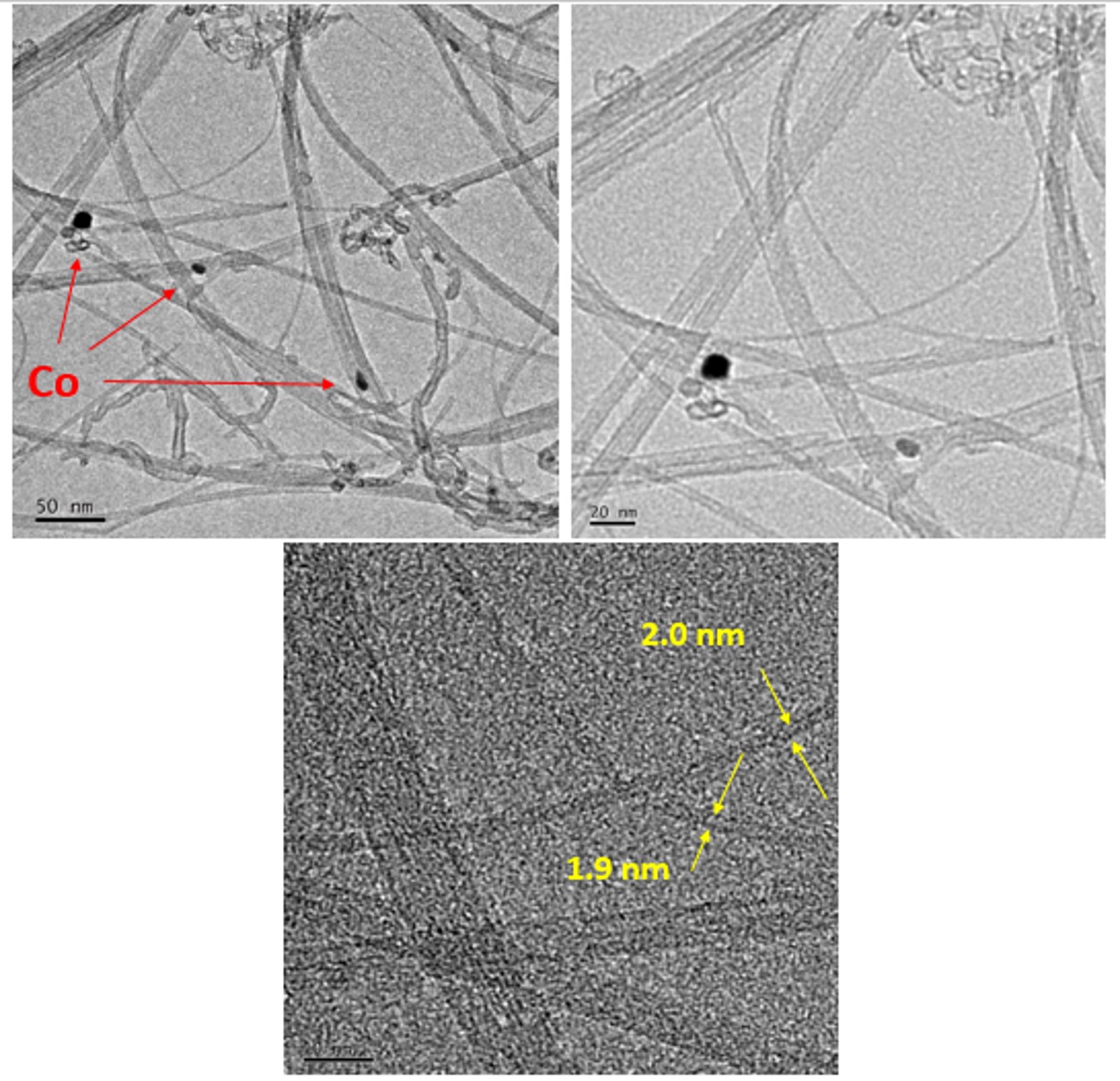

In this invention, plastic waste is processed catalytically to generate highly valuable nanomaterials, mainly single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs), with very low energy consumption and very little emission of global warming gases. Nanomaterials have wide applications in electronics, batteries, energy storage, etc. The process is self-sustainable and does not require any external energy source. We disclosed here the process design, operation conditions and catalysts with minimum energy input for the maximum output, including more quantity and high quality of nanomaterials, low emission, no odor, and so on. This invention also disclosed a reactor for the plastic waste treatment so that the developed process could be done in factory scale.

Figure TEM images of SWCNTs and MWCNTs formed on CVD catalyst Co-Mg.