Smooth Composite Membranes for Reverse Osmosis & Nanofiltration

Opportunity

Thin film composite (TFC) polyamide membranes have long been used for reverse osmosis and nanofiltration in water and wastewater treatments as well as other industrial applications. These membranes are used for their distinctive ability to separate and split ionic and comparatively small molecular organic matter from liquids, including water. Typical TFC membranes, however, have high surface roughness in the range of 50 to 150, which is a direct result of the manufacturing process. An uneven surface encourages fouling (the accumulation of particles) and this is known to degrade membrane performance over time. Earlier attempts to produce a smooth TFC membrane have proven complicated and difficult to scale up. In addition, the formation of polyamide thin films can only be conducted on porous support material with certain characteristics. At times, the raw support material has to be modified in order to fit the above requirement. This greatly limits the types of support material that can be used in TFC membranes.

Overcoming these limitations may help companies ride on the growing global reverse osmosis and nanofiltration membrane markets, which are expected to be worth US$13.5 billion and US$845 million respectively by 2025.

Technology

This invention discloses a free-standing technique for the formation of smooth thin film composite (TFC) membranes for fouling-resistant reverse osmosis and nanofiltration applications. It allows the formation of smooth selective thin films independent of the material used for porous support, hence, removing the need for the material to be pre-treated. It also does not call for the addition of expensive or toxic chemicals. In fact, this method reduces chemical consumption and shortens the production line of conventional TFC membrane fabrication processes.

This demonstrates its potential to produce low-cost, fouling-resistant reverse osmosis and nanofiltration membranes in a quick, simple, and more commercially-acceptable manner.

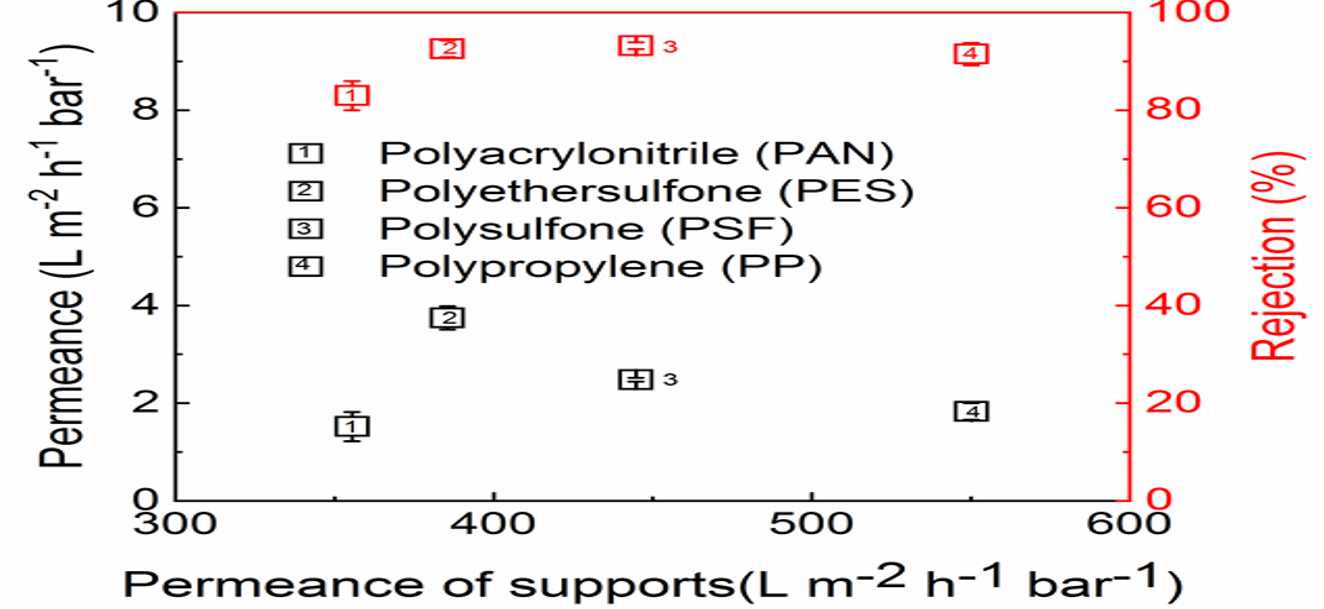

Water permeability and NaCl rejection of the TFC membranes prepared on different supports via free-standing interfacial polymerization.